The Swan

The Swan is an integrated partition set which is attached into the corrugated carton during box production rather than at the bottling plant. It uses 50% less material than standard assembled bottle partitions, and eliminates the need for partition assemblers and inserters. It is also designed to work with existing case erectors, and needs no significant alteration to your current carton flow.

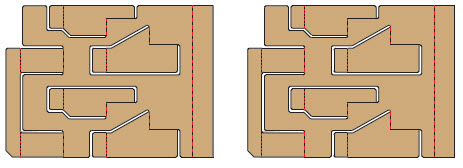

The Swan consists of either one or two die cut pieces, usually constructed of corrugated or heavyweight solid fiber material,

which is glued onto the inside of a corrugated 6 or 12 pack during the box making process. The insert then automatically forms when the outer case is erected, either in a standard case former, or by hand.

The Swan consists of either one or two die cut pieces, usually constructed of corrugated or heavyweight solid fiber material,

which is glued onto the inside of a corrugated 6 or 12 pack during the box making process. The insert then automatically forms when the outer case is erected, either in a standard case former, or by hand.

This new design has three primary advantages:

- Material Savings – The Swan uses die-cut ‘arms’ out of a corrugated sheet to separate the bottles, rather than the full length protection of a traditional assembled partition set. To adequately protect a 12 bottle pack, a standard set uses five pieces of material. Using 2.25 square feet of material, a savings of 50%. This savings translates both into potential cost reductions, as well as environmental benefits which will help your overall marketing message.

- Machine Savings – The swan is inserted by the box manufacturer using an attachment on a standard specialty folder gluer. These specialty folder gluers are currently used for all die cut cases, and the new attachment does not significantly effect run speeds. In turn, this replaces the need for both partition assemblers, as well as inserters, reducing both capital and operating expense.

- Process Savings – With the swan, you will no longer have to coordinate partition inventory to match box inventory, saving both purchasing hassle, as well as inventory space.

Proven Results

- Label and Bottle Protection – 50 minutes on a rotary motion vibration tester. Swan design performed equal in label and glass protection compared to traditional design for multiple bottle shapes.

- Compression Strength – Boxes were tested both on top to bottom compression strength, as well as side compression to replicate clamp trucks. The Swan outperformed traditional design in top to bottom by 58%, and by side to side by 16%.